Products | Materials Handling | Weba Chute Systems

With the current emphasis on reducing energy consumption, as well as promoting environmental issues, miners have quickly adopted Weba Chute Systems' solutions to minimise dust and pollution while promoting the lifecycle of equipment and reducing power consumption.

"Our locally manufactured Weba Chute Systems are designed according to the principle of conveyed material impacting on surfaces which already contain material," explains Mel King, of the MPE JV. "Using a 'cascade' system to create a 'super-flow' effect, we are able to reduce volumes of unwanted fines and associated dust."

The immediate effect of the decrease in unwanted dust and noise pollution is an enhancement of working conditions ,this impacts positively on the health of workers. Weba chutes minimise dust, decrease abrasion to wearing parts and consequently less maintenance is required, spillage is virtually eliminated, further reducing dust pollution.

Weba Chute Systems control direction, flow and velocity of the calculated volume of material by taking into account belt width, belt speed, material sizes, shape and throughput.

Each Weba Chute System is designed for specific applications, and can be utilised on new or existing projects.

To date, over 3000 installations, handling a variety of different materials have been implemented throughout South Africa.

Please visit the M&J Engineering website for more information.

|

|

|

|

| Controlled Discharge Chute | Crusher Chute System | Dividing Chute | Superflow Liner Chute |

|

|

|

|

| Mill Feed Chute | Screen Chute | Stacker Chute | |

|

|||

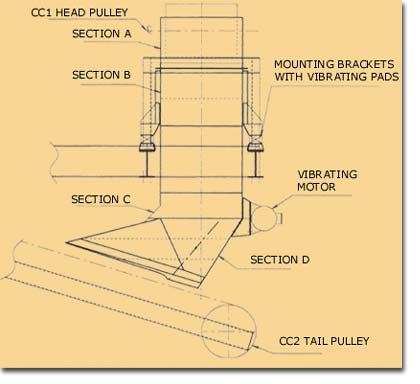

| Vibrating Chute | |||